©Copyright 2024 All right reserved by PROMAU ENGINEERING S.r.l.

Strada delle Industrie, 66 – 28062 Cameri (NO) Italy – Phone: 0321-510390 – Email: info@promau.it – P.I.: 01383290036

This term identifies the company that integrates all the necessary skills for the development, industrialization and mass production of a new component. Our goal is to provide each of our customers with an integrated service based on multiple skills and the ability to analyze and predict any problems related to product development. The success of each new project is the shared result of a team composed of different professional figures, of which the Customer is an integral part. The sharing of precise planning, which defines phases, costs and development time, is another fundamental step in our way of doing things.

For each project we plan all the factors involved: time to market, style and manufacturing requirements, investment in equipment, variable production costs, packaging and transport methods.

According to the targets of the development team, every single professional designs and industrialize the product and the production equipment either independently or in Co-Design with the Client, defining the most suitable materials, processes and technologies for each single application.

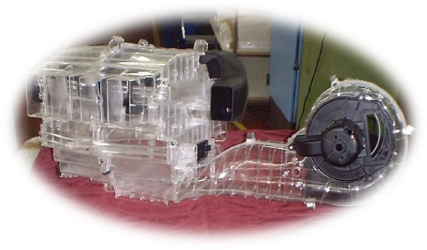

Always a leader in the use of Rapid-Prototyping technologies,, we allow customers to verify and test design solutions, both stylistic and mechanical, in a very short time, in order to identify any problems before making moulds and final equipment.

The reliability of these tests depends on the application of fundamental prerequisites, such as the know-how of the various prototype techniques, choice of the most suitable technology, definition of the most reliable materials, accurate finishing of the models and meticulous control entrusted to expert personnel.

Through the manufactured prototypes from silicone moulds it is possible to test the characteristics of the product even before having built the production equipment. The materials used are in fact formulated to simulate the characteristics of the final thermoplastic, thus making it possible to verify in advance the various operational requirements, such as vibration resistance, resistance to thermal stress, rigidity, flexibility, liquid crossing and sound absorbing.

It is also possible to obtain aesthetically perfect prototypes, with definitive finishing for the appropriate presentation to the final customer or for the early production of advertising leaflets or for possible exhibitions at trade fairs.

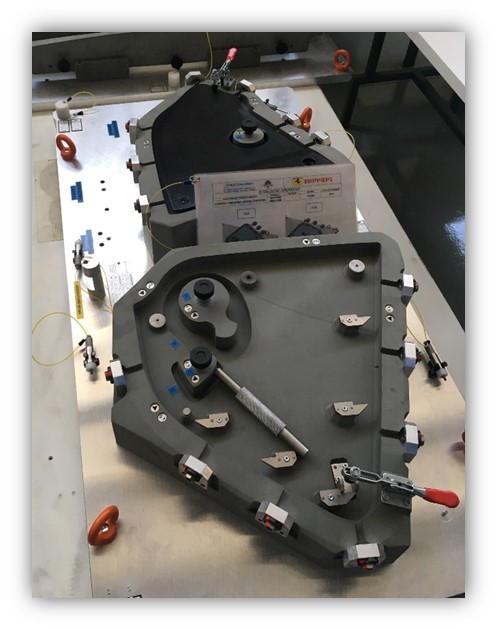

Our expertise covers the design and manufacture of moulds for series production in thermoplastic. The use of rapid tooling technologies allows to realize in a short time and at competitive costs the moulds necessary for either pilot or series production, both high or low volume.

The service also extends to the design and manufacture of complementary production equipment, jigs, laying, welding or assembly systems designed ad-hoc.

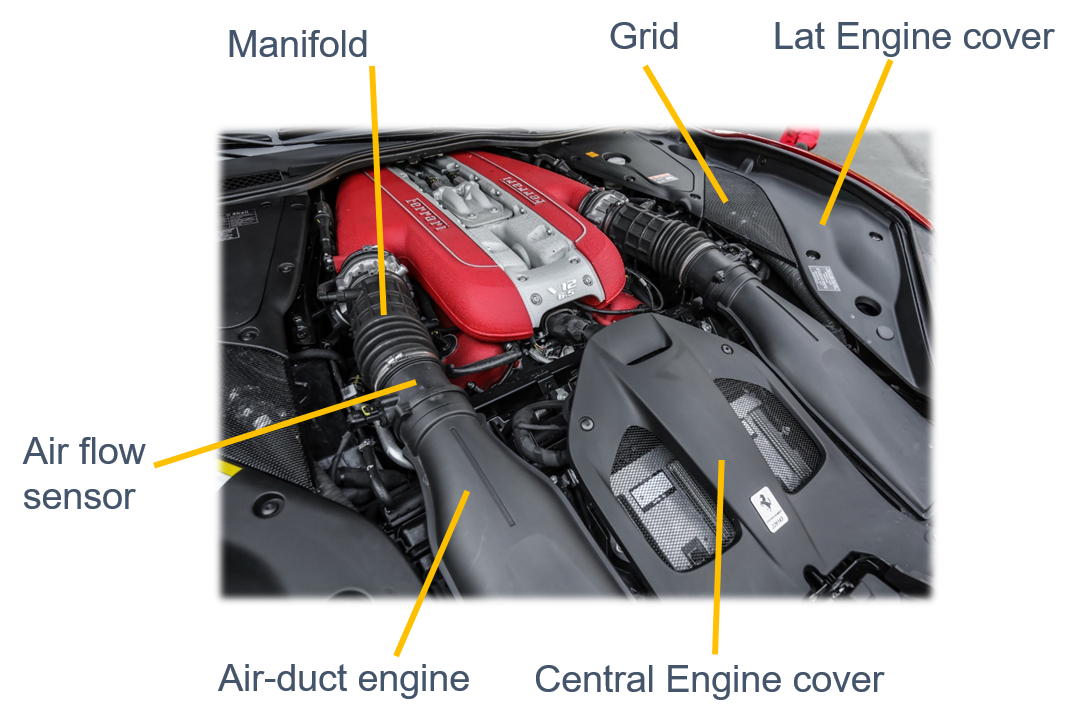

Since the early years of the new millennium, our services also include the mass production of thermoplastic components and assemblies, especially for the automotive sector. The materials cover a wide range of thermoplastic applications , from the common ones to the most sophisticated technopolymers.

The products we are responsible for include parts of the interior of the passenger compartment, which are characterised by high aesthetic standards, as well as engine components that are subject to considerable stress.

Our assembly department provides for the assembly and testing of the various assemblies with the relative kinematics, using various welding and insertion technologies, assisted by robotics.

Targeted investments in R&D have allowed our customers to have even more advanced processes.

In-depth research into materials and technologies has in fact led to the development of retractable and heat-sensitive paints on the one hand and the new microfibre coating on the other UV_Lux® marchio proprietario che sta diffondendosi in esclusivi settori di mercato.

Le microfibre UV_Lux® UV_Lux® allow to obtain velvety and softness touch on the surfaces through ultraviolet resistant colours and have successfully passed all the qualification tests of the Automotive sector.

| Cookie | Durata | Descrizione |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |